Structure

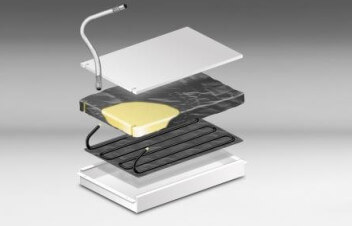

Structure of climate ceiling

- Gypsum panel 12.5 mm thick, supply and installation by third parties.

- Insulation layer above the gypsum panel, supply and installation by third parties.

- The AdeRo plastic climate mat counted with double-sided mounting tape against the above mentioned gypsum panel; supply and installation by Inteco.

- Pre-glued with Knauf Beto contact, supply and application by third parties.

- Spraying, thickness circa 14 mm, Knauf Machineputz MP75, supply and application by third parties..

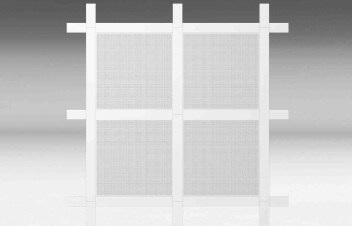

Climate mats

Climate mats made from polypropylene, consisting of two collection pipes with an internal diameter of 16 mm and wall thickness of 2 mm. Capillary pipes made from polypropylene, with an internal diameter of 2.3 mm and a wall thickness of 0.55 mm, have been connected to the collection pipes. The capillary pipes have been placed 15 mm from each other; this distance is safeguarded using spacing strips that have been placed horizontally on the climate mat at a distance of 200 mm (centre to centre). All fixed connections have been welded in the factory.

Dimension

AdeRo mats have a maximum length of 6,000 mm and a maximum width of 1,200 mm.

Connections

The collection pipes in climate mats are, depending on the spatial layout, number and size of mats, either connected using mirror welding couplings or connected separately to the main piping network.

Technical data

Technical data

The capacity of climate mats is determined by the implemented stucco and the thickness of the layer. In addition, possible capacities are also determined by the implemented spatial conditions and the water temperature. Considering guidelines issued by the manufacturer, as well as practical comfort-related limits, the average water temperature will be around 40 deg. C. When using as a heated ceiling, it is also important for air displacement to be realised along the ceiling so heated air does not stay in one place.

For indication purposes: possible capacities have been listed below:

| | Cooling: | Heating: |

| Water process: | 15-18°C | 43-37°C |

| Average water temperature: | 16,5°C | 40 °C |

| Spatial temperature: | 25 °C | 21 °C |

| Thickness sprayed finish: | 12 mm | 12 mm |

| Heat conduction coefficient: | 0,87 W/mK | 0,87 W/mK |

| Net capacity: | 67 W/m² | 126 W/m² |

Water quality

The plastic climate system must be secondarily separated from the primary piping system using a stainless steel heat exchanger (supplied by third party). Additives should not be added to the water because all products encountered in the secondary circuit must be made using plastic or corrosion-proof materials. Tap water of drinking quality, together with corrosion-proof and/or plastic materials, enables the system to operate reliably and prevents the system being blocked by build-up in the pipes. In addition, it helps to reduce annually recurring costs for checking and conditioning water quality.

Operating pressure

The system's maximum operating pressure is 4 bar.

Pressurisation

After installation (and before the stucco layer is applied), the climate system must be pressurised at 10 bar for a period of one hour.

Areas for attention

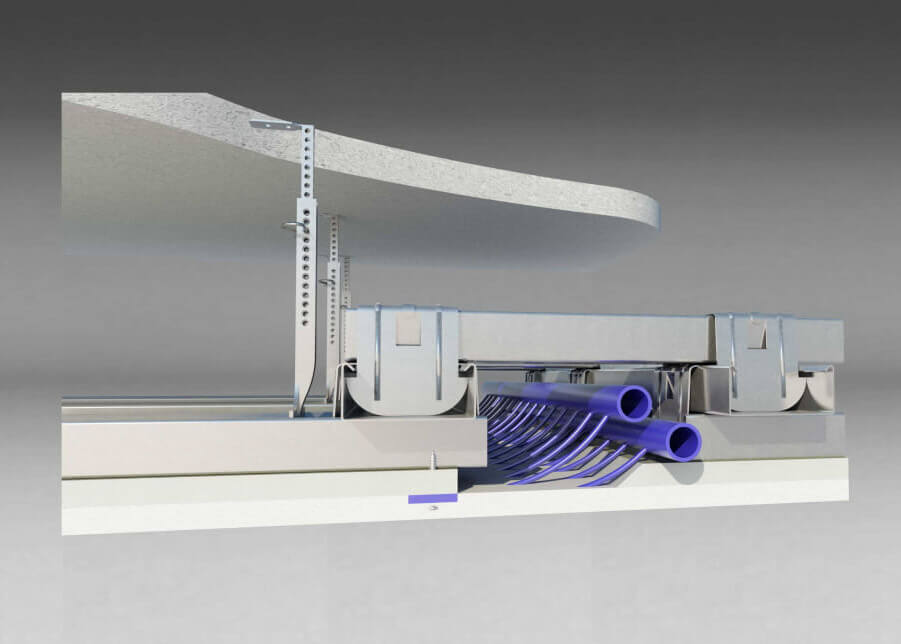

Gypsum ceiling:

To be supplied and installed by third parties. The support structure (Metal-Stud profiles or wooden battening) must feature a few openings for strips that will be left open in the ceiling. These strips are used to pull the wires of the climate mats up above the ceiling; after installing the mats, these strips can be covered using a plastering net, gauze or similar. Normal standard panels can be used when it comes to gypsum, although they must be dry when supplied and installed. In addition, the panels must be fixed in place using a lot more screws than used for a normal stucco ceiling. This is because the panels absorb a certain amount of moisture and because a thicker (heavier) layer of stucco is applied. It is very important for the plenum of the ceiling (certainly after applying the stucco layer) to be well ventilated. Due to the total mass of the ceiling (construction, insulation, gypsum panel, climate mats and stucco), Inteco recommends using rigid mounting devices like metal hangers or M-6 wire ends.

Stucco layer:

When applying the stucco layer, it is advised to keep the climate system under (water) pressure; the leak will be immediately visible if pipes are damaged during plaster work.

Climate system:

The plastic AdeRo climate system consists of capillary pipes and is made from oxygen-permeating polypropylene. The whole system can therefore be integrated into the main piping network as a secondary circuit, using a stainless steel heat exchanger. The whole secondary system must consist of corrosion-proof materials in order to prevent all pollution risks.

Other provisions in the ceiling:

Climate mats will need to be adjusted accordingly if e.g. spotlights, speakers, smoke alarms, etc. have been integrated into the ceiling. This means it may be necessary to use mats in different sizes and quantities.

Maintenance:

Climate systems in a plastered ceiling do no require maintenance. However, one must ensure the ceiling is not drilled or nailed because this could damage pipes and cause leaks. If this happens, the system must be shut down and plaster must be removed from around the leak. The damaged capillary pipe can then be sealed. ?

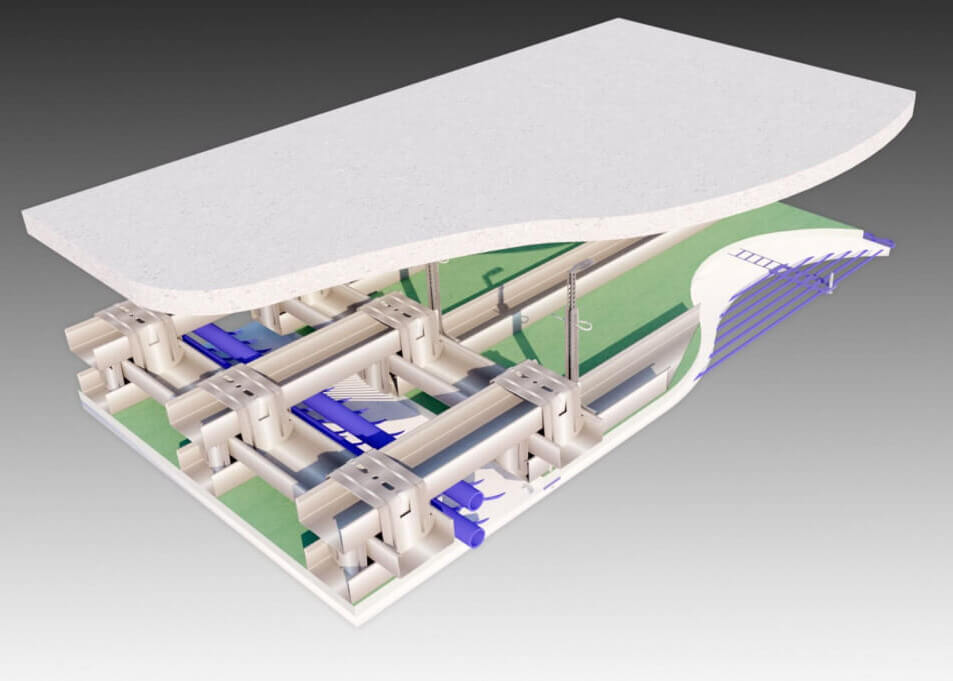

Comment:

As an alternative to the above mentioned use of a gypsum panel, it is possible to place climate panels directly against the concrete surface. In this case, adhesive features can be applied to the climate mats in the factory, therefore allowing them to be easily installed against the concrete. This is followed by the same approach as when applying against a gypsum panel, namely:

- Pre-gluing with Knauf Beto contact 90, supply and installation by third parties.

- Spraying, thickness circa 14 mm, Knauf Machineputz MP75, supply and installation by third parties.

However, when installing climate mats directly against concrete, separate measures must be taken to conceal distribution and collection pipes, possibly via a gypsum cove.