Operation

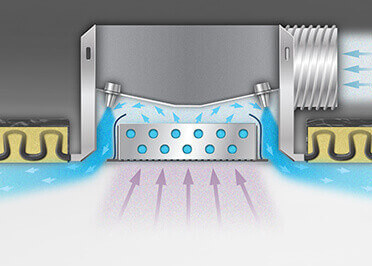

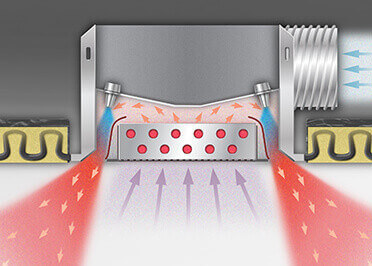

The inflow direction will be adjusted automatically depending on the inflow temperature. When cooling, air is blown along the ceiling (Coanda-effect). When heating, the position of the valve is adjusted so a variable angle is created to blow hot air high into the relevant space. This allows the system to ensure uniform temperature and a high level of comfort.

Primary (fresh) air is blown into the unit's induction zone via 2 rows of aerodynamic discharge nozzle. These nozzles are inter-changeable, which means units can be easily modified to suit the new situation if there is a change in the function of the relevant space. The units can be adjusted to suit any situation because nozzles are available in various sizes. The bottom panel of the unit features a hinge, which means the insides of the unit, including the heat exchanger, can be reached and cleaned easily.

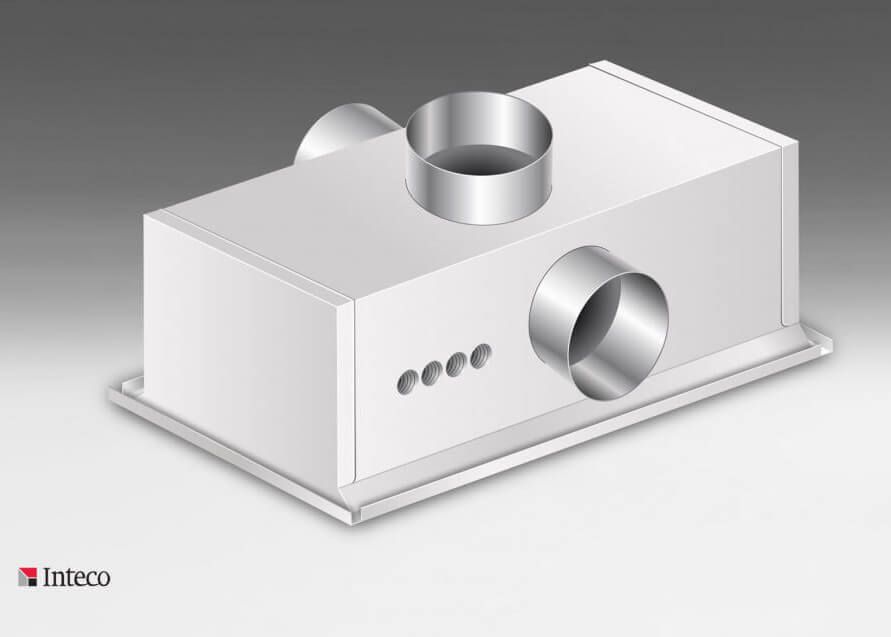

This flexible induction unit can be integrated into all ceiling systems, or be installed separately on a structural .

Technical specifications

Panel

The bottom panel is created using a perforated plate.

Nozzles

The specially designed discharge nozzles have an aerodynamic design to ensure low air-related pressure loss. These nozzles also ensure the VivesCo unit has low noise capacity. The Nozzles are available in three different sizes: S, M and L. This means air discharge speed, noise capacity in the unit and pitch can be determined individually and the best possible configuration can be found for each situation.

Implementation

The unit can be integrated into various ceiling systems. This modern, streamlined unit is available in various lengths, RAL colours and shine finishes. It is also possible to fit the unit with specially designed bulkheads for non-standard ceiling systems. Discuss the possibilities with one of our advisors.

Dimensions and connections

Dimensions and connections

The VivesCo A series is available in widths of 300 mm and 600 mm. Various lengths are also available

The VivesCo A series is supplied complete with connection set for effective water connection. The maximum water-related operating pressure in the VivesCo A induction unit amounts to 8 bar. This connection set consists of flexible oxygen diffusion-proof hoses that can be fitted with various connection options. Connections sets are available for 2-pipe (change-over) and 4-pipe (separate) systems. Integrated control valves are available as options.

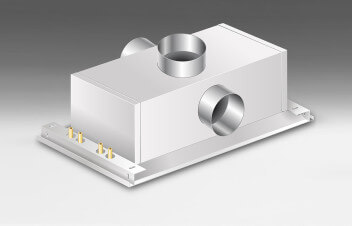

Air connection

The standard diameter of the air connection is 100 mm. In case of side connection, the connection spout will already be mounted to the unit casing. In case of top connection, the connection spout will be supplied separately along with a cap for the opening. This can be easily installed using the accompanying screws. In case of top connection, a 125 mm air connection is available as option.

Water connection

The factory-mounted flexible water hoses feature a 12 flat-sealing union nut in the two-pipe system. In four-pipe systems, the hot water connections feature a 3/8 flat-sealing union nut. The accompanying packing must be used to ensure a leak-free seal. To ensure the unit works effectively, it is important for the water supply to be connected to a coupling marked SUPPLY and for return water to be connected to a coupling marked RETURN.

Mounting

Mounting in a T girder ceiling:

VivesCo ceiling induction ceilings can be placed in a T-girder support construction. However, the unit must be mounted on a separate deck. That is why the units feature two mounting holes on both sides.

Mounting in a C grid ceiling:

The VivesCo ceiling induction unit can be placed on the C grid using the accompanying mounting brackets. The C grid must be mounted to the structural ceiling in a responsible manner, so it is able to support the unit. We also recommend mounting the unit separately to the structural deck. That is why the units feature two mounting holes on both sides.

Separate mounting

If the VivesCo ceiling induction units are not mounted in a ceiling-based support construction, then they can be mounted on the structural deck. That is why the units feature two mounting holes on both sides.

Use and maintenance

An innovative hinge system means the bottom panel can be easily opened for cleaning activities. A vacuum cleaner can be used to remove dust from the bottom of the extraction grid, and the surface can then be wiped with a moist cloth. Dust can also be removed from the inside of the heat exchanger. The bottom panel first needs to be opened, by reaching into the diffusion opening and pushing the spring blocks outwards. Additional activities must be carried out using a Ph neutral cleaning product. For the rest, VivesCo ceiling induction units are maintenance free.