Operation

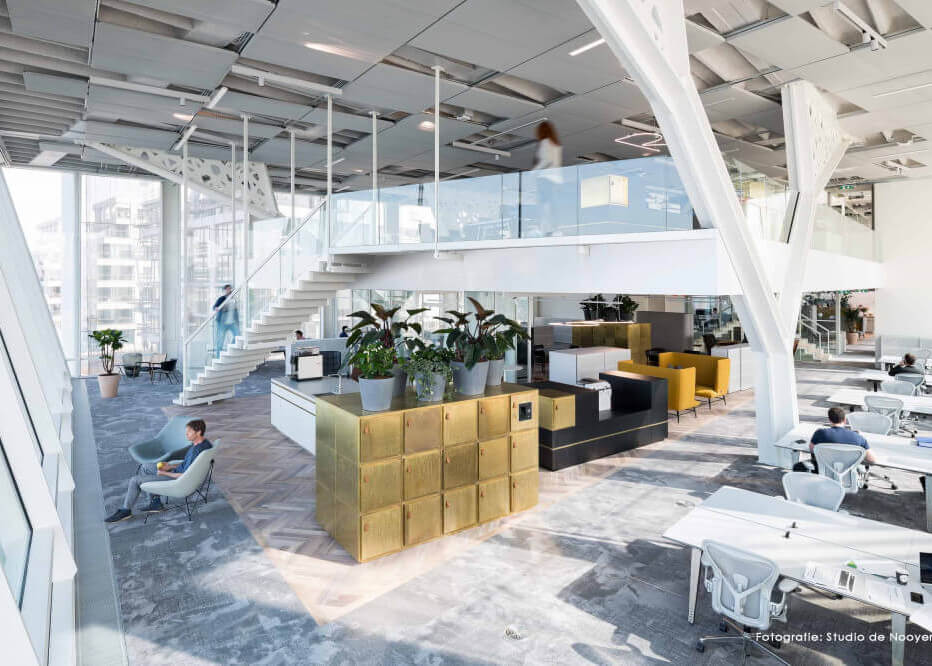

The MeandRo-V element can be visibly or invisibly incorporated into the ceiling and allow air in the relevant space to circulate through it, therefore creating higher convection transfer compared to conventional climate ceilings. In conventional climate ceilings, where the climate element is enclosed between a metal panel and the acoustic package, approx. 60% of the cooling capacity is transferred via radiation and approx. 40% via convection. That is why they are often referred to as radiant ceilings. The MeandRo-V climate ceiling realises a (much) higher convective contribution. The convective contribution is 70% in completely open MeandRo-V ceilings, which means cooling capacity has been doubled compared to a radiant ceiling. The rolling air created by the MeandRo-V climate ceiling is uniform, silent and has low speeds, and does not reach the living zone. The MeandRo-V climate system can distinguish itself from convective climate systems due to the ease with which high cooling capacities are realised.

In principle, the MeandRo-V climate ceiling can also be heated. Even when cooling, the increase in convective transfer improves the capacity realised via water. Because hot air rises, ceiling height and the injected ventilation air will determine what contribution the convective part of the heating capacity makes to thermal comfort in the relevant living area.

The MeandRo-V climate ceiling can be fitted with noise-absorbing material. Depending on the structure, noise-absorbing material could hinder the connective effect and hinder the generated cooling capacity. Maximum cooling capacity is realised by creating the largest possible air shaft above MeandRo-V climate elements and by placing acoustic material directly against the under-side of the structural ceiling.

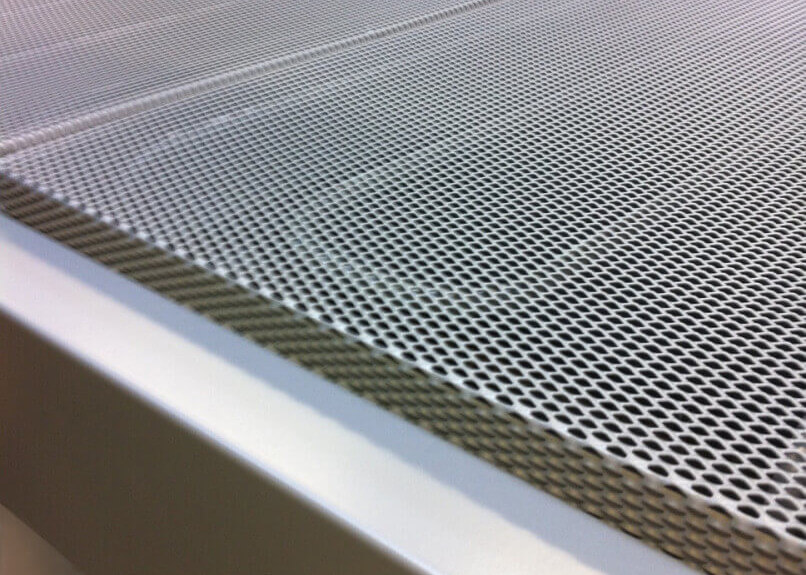

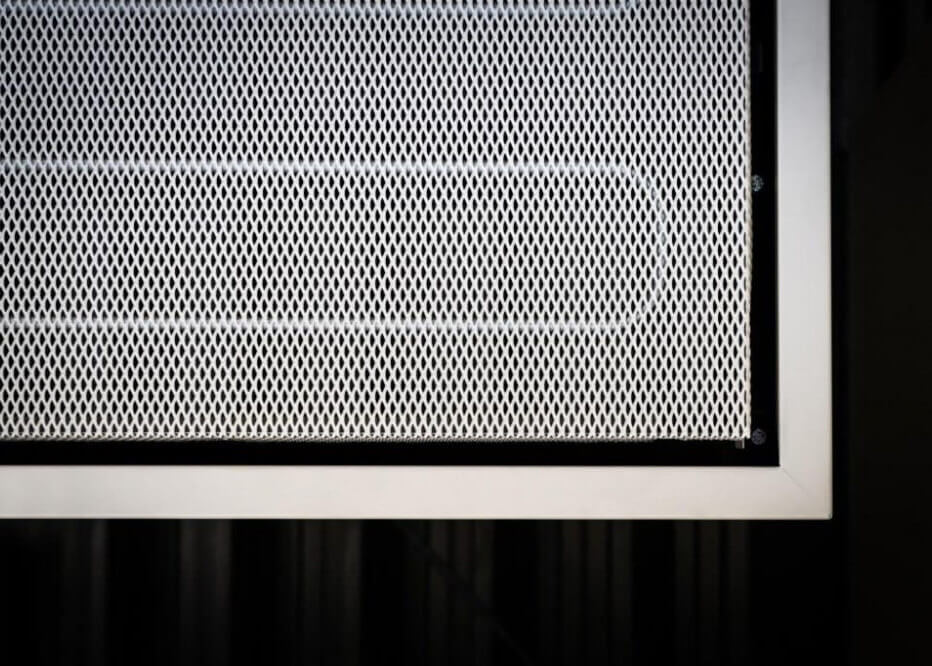

The MeandRo element is incorporated into the ceiling panel in Inteco's own production facility. This element consists of a copper pipe for water supply, measuring 8 x 0.5 mm and running back and forth, the full length of which is soldered on to aluminium expanded metal with an open structure. The expanded metal helps to laterally transport heat. And effectiveness is increased significantly because the pipes run in a perpendicular direction. The large surface and the open structure ensure effective and uniform heat transfer between the MeandRo-V element and the relevant area (air). During the heating process, the MeandRo-V element serves as a radiant panel and convector, and heat is released into the relevant area The opposite is true when it comes to cooling. This means heat is extracted from the area in question via the MeandRo-V element.

The use of copper pipe and flexible connection hoses means the system results in almost no oxygen diffusion. Because water is low in oxygen, almost no corrosion is encountered and trouble-free operation can be safeguarded. The permissible operating pressure amounts to approximately 8 bar, which means several storeys can simply be included in a single circuit.

The MeandRo element only has limited water content and therefore low heat content. Therefore the MeandRo climate system quickly responds to temperature and/or volume fluctuations in the water supply. This means the MeandRo climate system is ideal for change-over systems.

Technical specifications

Capacity

External factors like sunlight, transmission data for windows, walls and roofs, and internal factors like heat development via e.g. other people, electrical equipment and lighting, are used to define cooling and heating capacity per area when designing the climate system. This also involves taking into account variable effects like fluctuating solar load, heat accumulation due to e.g. concrete constructions, extraction via light fixtures, etc. The designer also determines the benchmarks implemented for comfort. Inteco then uses the design benchmarks to determine the layout of the MeandRo-V ceiling. Even high cooling capacities can generally be realised with the MeandRo-V ceiling.

The effective heat exchange and large heat-exchanging surface help to realise cooling capacities of approx. 100 à 190 W/m² (ΔT = 8K).

Pressure loss

During the execution phase of each project, pressure loss is calculated for each connection point in the climate ceiling.

The following details are important when doing so:

- Volume

- Average water temperature

- Dimensions of climate elements

- Connections (series / parallel)

Inteco aims to realise pressure loss of between 5 and 40 kPa, which can be realised by creating appropriate connections (series / parallel) between the MeandRo-V elements.

MeandRo climate elements

- Expanded metal: Aluminium. Meander: Copper pipe ø 8 x 0.5 mm, horizontally soldered on to the expanded metal.

- Mounting: Clamped into a frame (flat element) or placed on top/attached (sloping element).

- Series connection: Flexible, oxygen diffusion-proof hoses with braiding and manifolds.

Distribution pipes

- Material (mm): plastic RIXc (PE-Xc/AL/PE-Xc) ø 20 x 2.

- Branches: ø 10 mm, suitable for attaching John Guest manifolds.

- End surface: smooth edge.

- Mounting: plastic pipe brackets Comment: Distribution pipes can also be made using copper pipes or thin-walled CH pipes combined with compression fittings upon request.

Hydraulic details (cooling and heating)

- Water quality: Water treatment is unnecessary for the MeandRo-V climate system and the materials implemented by Inteco.

- Operating pressure: Maximum operating pressure amounts to 8 bar.

- Pressure loss and volume: Between 5 and 40 kPa, volume determined by the balance between series connections.

Acoustic performance

- Noise absorption: Upon request, depending on the layout NRC up to 0.90.

- Noise insulation: Not possible

Combi elements

The MeandRo-V element is ideal when implementing a completely separate system for cooling and heating. This can be attributed to the use of so-called MeandRo combi elements, where special cooling and heating meanders are interwoven to create a single element. Cooling and heating pipes are therefore located interchangeably.

Main installation and configuration

Climate system controls

Configuring capacity

The cooling and heating capacities of the ceiling can be set per configuration zone. The configuration zone is that part of the ceiling which has connected controls for realising the required capacity. Configuration can involve a whole building, part of the building (e.g. north/south side), a room or even a fixed pattern, and therefore offers great flexibility. The controls can be arranged centrally via the building management system or via a regulator in the relevant space.

Control based on variable volume flow

This control method assumes a constant temperature in the water supply. Room temperature is regulated by reducing or closing water supply via a two-way, three-way or six-way valve.

Control based on variable temperature

This control method assumes constant water volume. Room temperature is regulated by centrally varying the water supply temperature via the building management system.

Dew point protection

Central dew point protection

Various parameters, like the dew point temperature measured for outdoor air, return air and the air in reference rooms, are used to centrally regulate water supply temperature via the building management system.

Passive dew point monitoring

A dew point sensor, which is installed in the ceiling, detects potential condensation at an early stage; the control valves will shut off water supply to the relevant configuration zone in that case. If the building has windows that can be opened, dew point sensors are often incorporated into window contact surfaces.

Active dew point monitoring

A room-based regulator continuously calculates the dew point per configuration using relative humidity and room temperature. The water supply temperature is varied per configuration zone, which stops condensation from occurring. The water supply temperature can, for example, be differentiated using a mixing switch between return and supply in the relevant area. This type of monitoring means an extra pump is needed per configuration zone. Active dew point monitoring is often combined with central monitoring, which means only critical areas are actively regulated.

Structure climate system

Cooling and heating can be realised as follows:

Using a completely separate system for cooling water and central heating water

- Separate elements

Different panels are used for cooling and heating in the energy favourable, completely separate hydraulic system. This means one panel is connected to the cooling circuit, while the other is connected to the heating circuit. This system is effective for buildings where lower capacities are required. - Combi elements - A good alternative for MeandRo combi elements, where special cooling and heating meanders are interwoven to create a single element. Cooling and heating pipes are located interchangeably. Each active panel can therefore serve for cooling and heating purposes. This means combi elements are suitable for offices where higher capacities are required.

Via a change-over system

- 2-pipe system

The whole pipe network and climate elements will therefore be flushed with cold water during cooling; with hot water during heating and with a mixed flow during the change-over period (transition between cooling and heating or vice versa). In this system, a lot of water needs to be heated to heating temperature (and vice versa) during the long change-over period, and that consumes energy. This easy to install system is therefore particularly suited to smaller circuits. - 3-pipe system

In this system, the main pipes for cold and hot water supply are separated until immediately prior to the climate ceiling in the relevant space. That's where both pipes are combined using a three-way valve. The distribution pipes, climate elements and return pipes are all shared. This concept enables high reaction speed and shortens the change-over period, while a lot less water needs to be heated and cooled. - 4-pipe system

This system involves double supply and return. They are only shared in the climate ceiling. The two supplies are joined at the three-way or six-way valve, just like the 3-pipe system. However, in this case, the return flow is also separated via a similar three or six-way valve. The 4-pipe system combines high reaction speed with a short change-over period, where almost no energy destruction is encountered.

Ventilation

Inteco has compiled a ventilation protocol for ventilating climate ceilings. This is discussed with construction partners during execution of the project so the climate ceiling can be ventilated in an appropriate manner. After all the preparation activities (filling, etc.), the prescribed flow must be conventionally ventilated per section. Because the internal diameters of climate elements and flexible hoses are relatively small, there is no chance of air being left behind in upright elements or hoses if there is sufficient water flow. Air bubbles are easily propelled and eliminated by the water flow. However, each section must be ventilated separately in order to ensure sufficient flow in each series connection. This is possible, for example, by implementing central ventilation whereby only one section is opened at any given moment. Followed by the next section, etc..

Sustainability, fire safety & certification

Production and environment

All ceiling products are produced in accordance wit the TAIM norm (Technischer Arbeitskreis Industrieller Metalldeckenhersteller). Only a small amount of production waste is produced during the production process for climate elements, while 100% of the basic material is utilised. During soldering activities for the MeandRo element, released gases are carefully extracted and filtered in accordance with the strictest norms. All parts of the ceiling and climate element can be easily sorted by material type, and can be recycled into high quality raw materials. Inteco's climate ceilings are ideal for projects where certification in accordance with BREEAM, for example, is required.

Fire safety

A feeling of safety. Inteco advisors are familiar with international requirements implemented for fire resistance, flammability and fire stability. They are perfectly placed to know which provisions are needed in order to comply with these requirements. Inteco's products and systems have been tested for their fire behaviour in accordance with the EN standard 3694.

Certification

Inteco is synonymous with quality and reliability. That is why we think it is important for our products and processes to comply with the strictest norms and certifications.

- Inteco is ISO 9001 and ISO 14001 certified

- Our employees are VCA certified

- Inteco climate systems are tested in accordance with applicable European norms, e.g.: EN 14240 / EN 14037 / EN ISO 7730

- Inteco ceiling systems feature CE markings, including Reaction to Fire Classification (SBI test)