The highest level of functionality and comfort

Powerful via simplicityInteco's ceiling induction units can be used for new-builds and renovations, and can generate ventilation, cooling and heat in buildings. A comfortable indoor climate can be realised based on the ceiling plan. Induction units can be used for cooling purposes in buildings featuring systems with radiators and floor heating, but can also be used as the main system for heating and cooling.

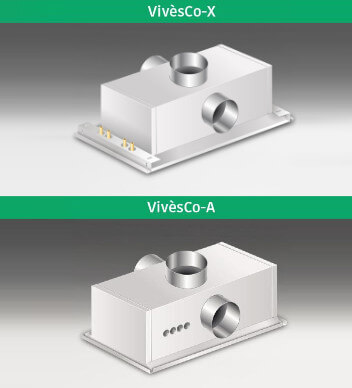

Operation VivèsCo-X induction-unit

The VivèsCo-X series operates based on the crossflow induction principle developed by Inteco. The ventilation plenum, where primary air is connected, is located at the top of the casing. An induction zone has been realised below this, with the lower panel featuring a water-transporting heat exchanger. The aerodynamic nozzles under the ventilation plenum blow primary ventilation air into the induction zone, without the air streams touching each other. This flow can realise strong induction because the air flow covers a relatively long distance in the unit, and because air speeds contrast with each other. This means more secondary air can be attracted across the heat exchanger (high induction rate). Mixed air (primary and secondary) is then blown into the relevant space via the outflow opening at the bottom of the unit. The outflow opening has been placed so out-flowing air passes along the ceiling and, due to the coanda effect, continues to travel along the ceiling over a long distance to create the desired cooling or heating.

2 rows of aerodynamic discharge nozzles are used to blow primary (fresh) air into the unit's induction zone. These nozzles are inter-changeable, which means units can be easily modified to suit the new situation if there is a change in the function of the relevant space. The units can be adjusted to suit any situation because nozzles are available in various sizes. The bottom panel of the unit can be opened, which means the insides of the unit, including the heat exchanger, can be reached and cleaned easily.

This flexible induction unit can be integrated into all ceiling systems, or be installed separately on a structural construction.

read more about the VivèsCo-X

Operation VivèsCo-A induction-unit

The inflow direction will be adjusted automatically depending on the inflow temperature. When cooling, air is blown along the ceiling (Coanda-effect). When heating, the position of the valve is adjusted so a variable angle is created to blow hot air high into the relevant space. This allows the system to ensure uniform temperature and a high level of comfort.

Primary (fresh) air is blown into the unit's induction zone via 2 rows of aerodynamic discharge nozzle. These nozzles are inter-changeable, which means units can be easily modified to suit the new situation if there is a change in the function of the relevant space. The units can be adjusted to suit any situation because nozzles are available in various sizes. The bottom panel of the unit features a hinge, which means the insides of the unit, including the heat exchanger, can be reached and cleaned easily.

This flexible induction unit can be integrated into all ceiling systems, or be installed separately on a structural.

read more about the VivèsCo-A

General characteristics and benefits of VivèsCo ceiling induction units:

- air injection during cooling via coanda effect;

- air injection during heating via coanda effect or high into the area via induction;

- easy to exchange and access nozzles;

- singular and double injection possible;

- powerful and stable injection pattern;

- available in various lengths, colours and versions;

- customisation possible for integration in various ceiling systems or freely hanging in the area;

- maintenance friendly and easy to clean;

- suitable for PPS projects;

- fully recyclable.