The customized vision of Inteco

The customized vision of Inteco: Comfort without Compromise For more than 20 years, the credo of Inteco has been 'Comfort without Compromise'. We offer a complete comfort experience and make no concessions. Within our project-driven approach, the phase in which we identify customer requirements is essential. Our goal is not only to provide a climate ceiling, but to ensure a complete ceiling integration in the building concept. It is the rule rather than the exception for us to look beyond our own field. This is the distinctive character of Inteco. So we not only look at the climate ceiling, but also think along with you on related expertise such as air regulation, lighting or interior architecture. We go for a comfortable indoor climate.

What does the customer want and what is possible in a building Facilitating an optimal comfort experience is not only in the tangible materials and functionalities at Inteco, but also in our expertise and professional project management. We think along with you throughout the entire project and our method is aimed at relieving you. In the field of aesthetics, a practical example of our proactivity is the calculation of a ceiling so that no (deviating) narrower strips are visible. Or think of bandrasters that fall exactly in the middle of two frames. Points for attention that are self-evident for Inteco and that contribute to an optimal integration of the ceiling into the room. For more examples and inspiration, please refer to our projects page.

The customization is technically done to perfection The customization often contains the distinctive details of a project. In addition to the hydraulic calculations, we also find it very important to work out the technical details for you. Within drawing, we do not limit ourselves to just the ceiling. As mentioned, we also look at related disciplines and how they integrate into the ceiling concept. If necessary, we will identify bottlenecks and propose improvement proposals.

We treat every workplace as if we ourselves have to work there every day. How does a customized process work at Inteco? We put together a multidisciplinary team based on a client's wishes or customized issue. They brainstorm with the R&D department about the possible solutions. In our own production facility we can directly produce the solution as a prototype and place it in the mock-up room. We then invite you as a client to assess the solution for aesthetic needs and implement improvements. If necessary, we test the application in Inteco's own test room for preconditions such as power and diffusion density. The entire process offers you, as a customer, additional certainty about the quality and aesthetics of your customized project

We work Lean! We work Lean! Thanks to our Lean working method, we have succeeded over the years in standardizing tailor-made processes in both production and project management. In our production facility, we work according to the one-piece-flow principle, which means that we do not produce complete projects, but frame units such as one floor. The result: fast lead times, no unnecessary storage costs and room for unforeseen building complications. In short: we have the capacity, literally and figuratively, to take care of your tailor-made process! View our projects and read about the challenges we face when it comes to customization.

Latest news

An optimal indoor climate. The basis for a good working environment

A good indoor climate in offices , hospitals and schools is a proven...

Read more

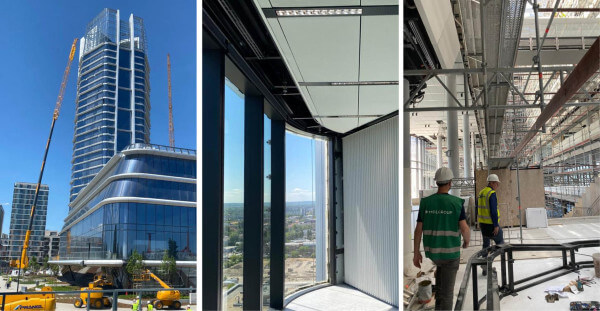

Visit MOL Budapest

Our colleagues have traveled to sunny Budapest for a project visit to MOL....

Read more

AFAS Experience Center

Software company AFAS has developed an impressive building in the...

Read more